How JAXA, NASA and European Space Agency are developing extraterrestrial autonomous construction using artificial intelligence

AI • Jul 18,2016

How JAXA, NASA and European Space Agency are developing extraterrestrial autonomous construction using artificial intelligence

The Japanese space agency has teamed up with construction company Kajima to develop autonomous construction machines for the moon and Mars. Earlier Nasa invested in revolutionary technology SpiderFab, which will create large-scale cosmic structures, such as spacecraft frames, farms of antennas, solar power plants and even large telescopes. In 2014 European Space Agency announced a plans town on the moon to replace International Space Station; construction could start as early as 2024. More and more space nations are looking towards extraterrestrial autonomous construction using artificial intelligence.

Plans to build human shelters on extraterrestrial bodies had been bandied about long before the rise of modern robotics. In 1959, 10 years before we first set foot on the Moon, the US government conducted studies exploring the feasibility of creating a military moon base, while the Soviet Union had plans for a lunar outpost of their own at around the same time.

In 2015 NASA launched architectural competition 3D Printed Habitat Challenge. Entrants were challenged to develop ‘state-of-the-art architectural concepts that take advantage of the unique capabilities 3D printing offers’, but also offer comfortable living spaces for future Mars inhabitants. The winning design was the Ice House, a luminous plastic igloo sheathed in a protective layer of ice.

A futuristic company Tethers Unlimited is developing a revolutionary suite of technologies known as “SpiderFab” to enable on-orbit fabrication of large spacecraft components such as trusses, solar panels, antennas, and other multifunctional structures. SpiderFab will manage spider robots as they construct these large structures, making the company’s effort an alternate way of deploying space systems. The structures can be larger because they will be constructed in the microgravity of space and not subject to the high forces of gravity at liftoff.

Existing large space structures now have to be constructed on Earth first before they can be sent to space, making them very expensive and also limiting their size and weight, since the unit has to fit inside the rocket or what’s referred to as a space shroud. With this new technology, spider robots could be controlled to build kilometer-scale radio antennas, solar arrays, and spacecraft booms among other components in outer space.

The vision that has motivated the effort to build things in space is that of creating a satellite “chrysalis,” composed of raw material in a compact and durable form, “software DNA” assembly instructions, and the capability to transform itself on-orbit to form a high-performance operational space system, according to Tethers Ulimited CEO Bob Hoyt.

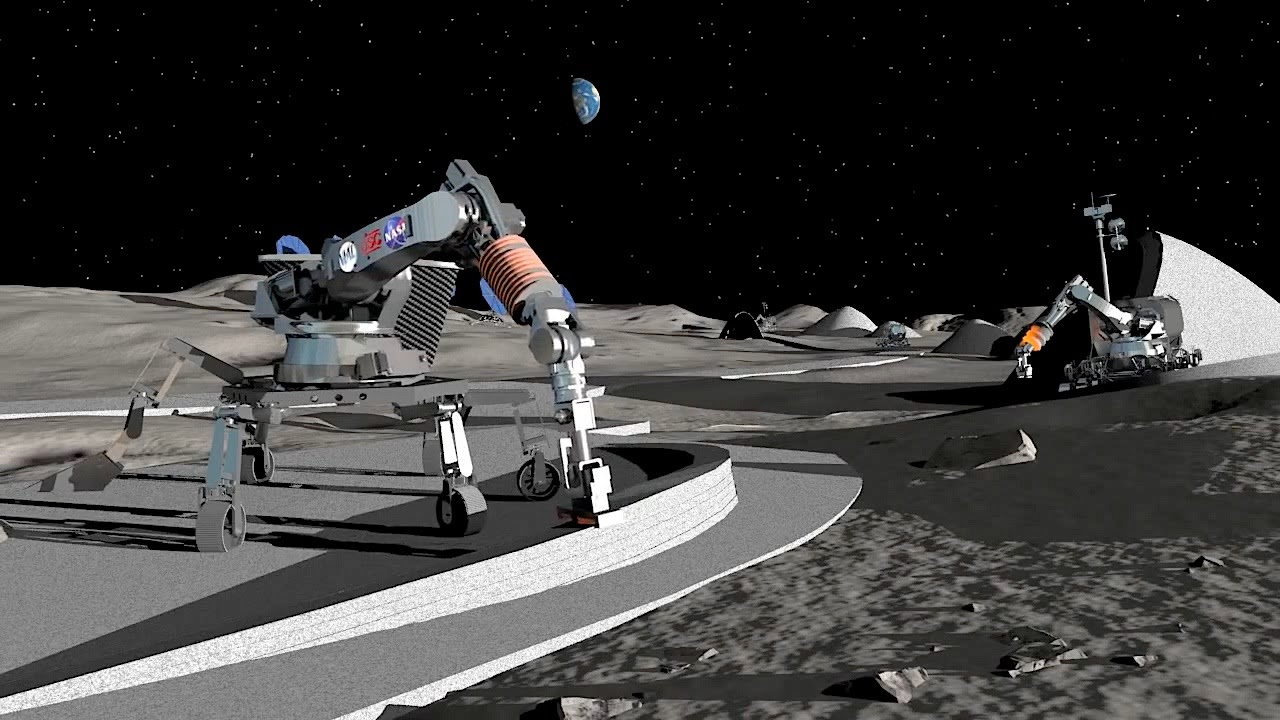

Japanese contractor Kajima plans to team up with the Japan Aerospace Exploration Agency (Jaxa) to develop automated construction machinery to work on construction projects on Mars and the moon. Nikkei Asian Review reports that the project will be an extension of Kajima’s A4CSEL system, an abbreviation that stands for Automated Autonomous Advanced Accelerated Construction System for Safety, Efficiency, and Liability. This allows operators to control machinery from a remote location using tablet computers, as well as GPS and accelerometer chips. According to Nikkei Asian Review, the company’s automated construction systems should allow the agency to build habitats for four to six people on the Moon in around 2030 and on Mars in around 2040.

The system was used last year to build dams in Fukuoka and Oita prefectures in southern Japan. According to Kajima, networked bulldozers carried out “simple and repetitive” construction operations with “high precision”. In an extraterrestrial setting, the concept could prepare the site for a building or launch pad and carry dirt. Kajima intends to develop its A4CSEL software so that the machines can communicate with each other to avoid repeating work or colliding with each other. This is necessary because the delay in sending signals from Earth would make them difficult to control in real time.

In January 2016, Jaxa selected Kajima’s idea to develop machinery for construction in space for its Space Exploration Innovation Hub project, a three-way programme among businesses, the government and universities. As well as Kajima, Jaxa is working with a number of other Japanese contractors on research projects. It has given the Taguchi Industrial Company the job of developing ultra-lightweight construction machinery, which would be easier to lift out of Earth’s gravity well.

European Space Agency, NASA and JAXA have all put forward plans to build space bases of one kind or another. 3D printing technology has helped bring such visions into the realms of possibility, particularly when casting the eye further afield to a certain dusty red planet. Artificial intelligence is a new step for clever autonomous robots that will be used in construction in open space or during colonisation of Mars and other planets in near future.

Author: AI.Business

If you like our articles, please subscribe to our monthly newsletter:

[mc4wp_form id=”763″]

Previos Article Artificial Intelligence and Machine Learning Explained

Next Article How drones are changing construction industry