AI Achieves 97% Accuracy in Precast Concrete Panels Inspection

A I • May 01,2024

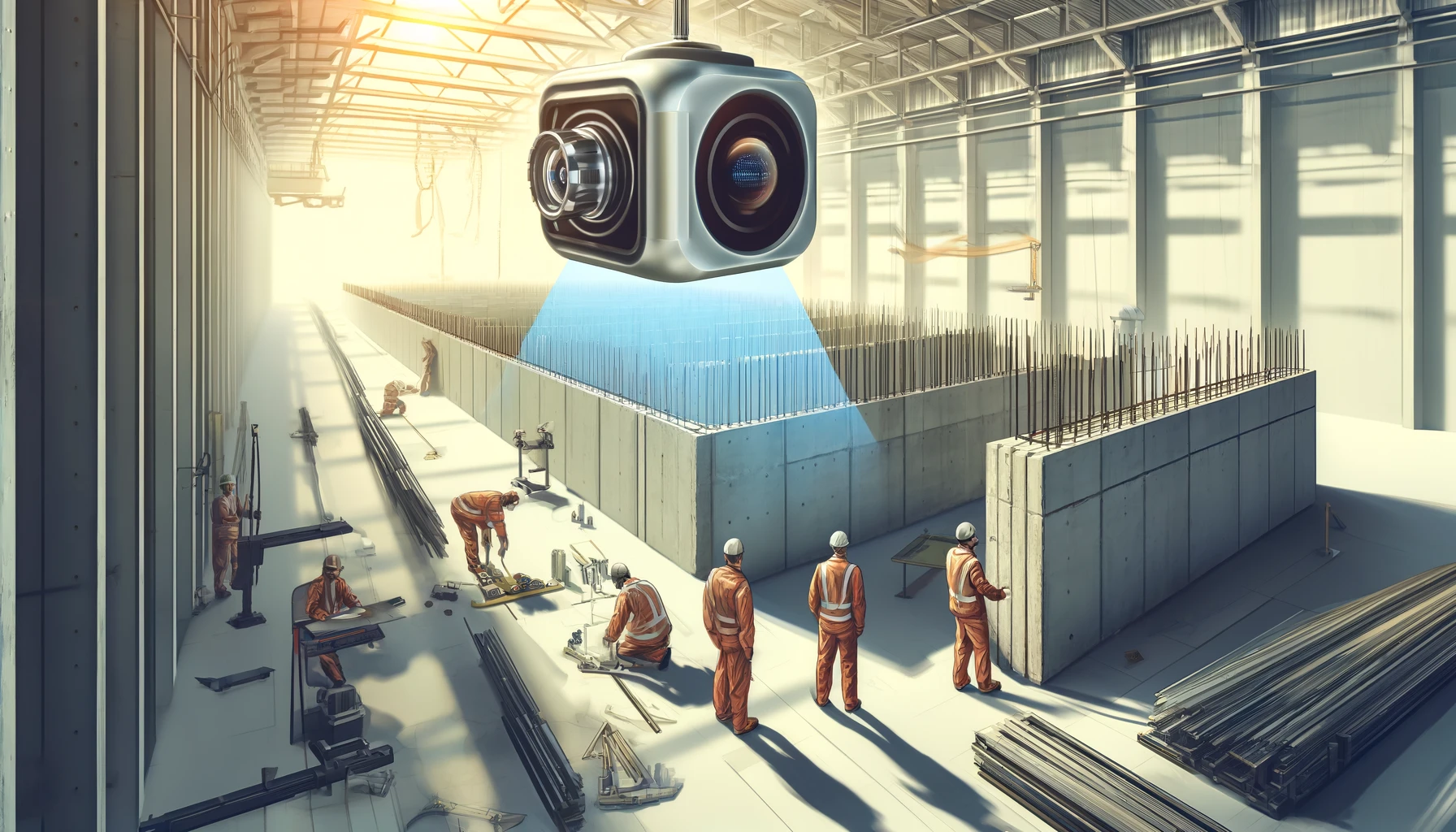

A construction company found manual precast panel checks slow and error-prone. To address this, it partnered with a research center and developed an AI tool with an overhead camera. This tool cut inspection time from hours to minutes and boosted accuracy, leading to faster, more reliable quality control.

Client:

Headquartered in Dartford, England, Laing O’Rourke is a renowned multinational engineering and construction firm. The United Kingdom’s largest private construction company, they are recognized for their innovative methods in building projects. A recent project by Laing O’Rourke, in collaboration with the University of Sheffield, focused on exploring the use of AI to improve construction quality assurance.

Problem Statement:

Previously, the quality assurance process for precast concrete panels suffered from inefficiency, errors, and time limitations due to its reliance on manual inspections. Inspectors relied on a combination of tools, including tape measures, printed CAD files, and mobile phones, to manually verify the number and placement of embedded objects within each precast panel. This manual approach lead to delayed project timelines, potential structural defects, and increased costs.

Results:

●For anchor pins: achieved an accuracy of 97% at the AMRC test bed and 70% at Laing O’Rourke’s factory.

●For other embeds: achieved an accuracy of 95% at the AMRC test bed and 73% at Laing O’Rourke’s factory.

●Even for a new type of anchor pin introduced later in the project, the system achieved a 92% detection rate on a single test image.

AI Solution:

Faced with time-consuming and error-prone manual inspections for precast concrete panels, Laing O’Rourke collaborated with the University of Sheffield Advanced Manufacturing Research Centre to implement an AI-based quality assurance system.

An AI-driven tool was developed to make the inspection of precast panels faster and easier. Instead of time-consuming manual work, the system utilizes a head-mounted camera to capture the panel and compare it to the CAD design file. AI algorithms designed by AMRC automatically detect and identify embedded elements on the panel.

Inspectors use a web application on a tablet to examine the panel visually, verifying the placement and number of embedded elements. The system synchronizes image data with the CAD file to identify any missing or improperly positioned embedded elements. Upon inspection completion, a PDF report is automatically generated and stored in a cloud database for future reference.

Laing O’Rourke’s Centre of Excellence and AMRC Factory 2050 served as the system’s testing grounds, and it passed with flying colors.

References:

1. AI-based Inspection Tool for Construction

Industry: Construction

Vendor: AMRC (Advanced Manufacturing Research Centre)

Client: Laing O’Rourke

Previos Article AI Scheduling: 13K Hours Saved and 323% ROI

Next Article AI-Powered Visual Inspection Delivers 95% Accuracy for Manufacturers