Energy Provider Achieves 96% Accuracy in Power Grid Inspections with AI

A I • May 05,2024

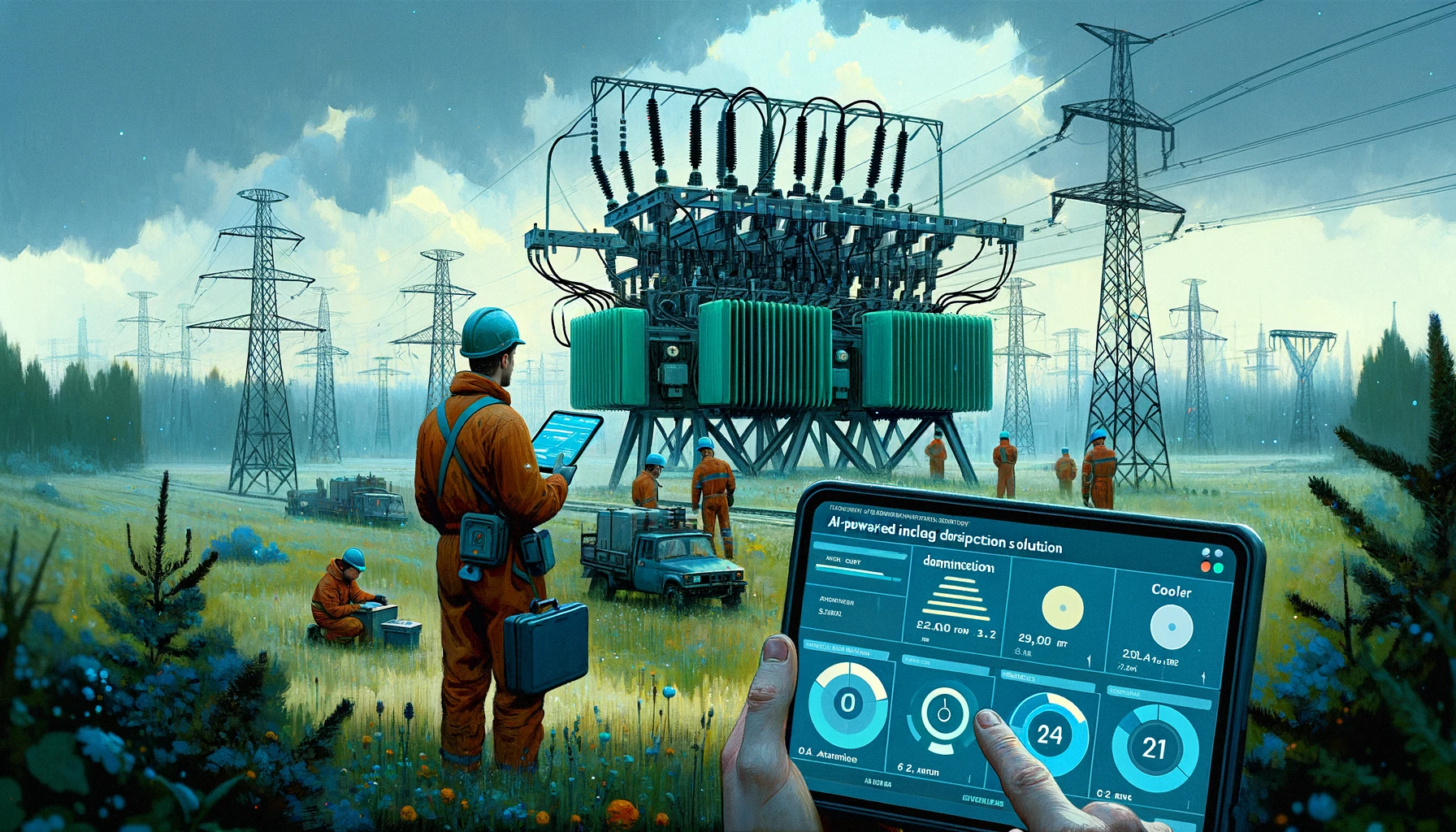

A Lithuanian energy provider had the problem of time-consuming and error-prone manual power grid inspections. They implemented an AI-powered inspection solution and achieved a 96% accuracy rate in detecting and classifying power grid components, a 92% accuracy rate in classifying defects within these components, and a significant reduction in inspection time and costs.

Client:

ESO, a leading Lithuanian energy provider, functions as the country’s electricity and natural gas grid operator. ESO is responsible for ensuring the stable distribution and supply of energy resources to Lithuanian homes and businesses, while also managing network connections, maintenance, and development of essential infrastructure systems.

Problem Statement:

The energy grid operator faced challenges in power grid inspections. They needed a more efficient and reliable way to ensure grid safety, reduce costs, and improve overall reliability. Traditional methods might have been time-consuming, prone to human error, or lacked the necessary detail for preventative maintenance.

Results:

High Accuracy Achieved:

- ● Grid Elements: 96% detection rate for power grid components.

- ● Insulator Defects: 92% accuracy in classifying broken insulators.

- ● Crossarms: 82% precision in identifying intact, tilted, and crooked crossarms.

Detailed Infrastructure Assessment:

- ● Concrete pillars: classified and assessed for cracks, tilts, and compliance.

- ● Wire clearances: calculated distance between lowest wire point and ground (and other objects) using LiDAR.

Vegetation Management:

- ● Efficient identification of vegetation near power lines with height, distance, and coverage data.

- ● Improved Safety Compliance: Based on voltage levels, the AI identified areas requiring special safety precautions, ensuring compliance with safety regulations.

AI Solution:

To overcome these challenges, ESO decided to use artificial intelligence (AI). The AI solution, developed by EasyFlow, automates key parts of the inspection process, working like this:

Spotting and Sorting Grid Components: The AI can accurately identify and categorize different parts of the power grid, like insulators and crossarms, with success rates up to 96%. It can also pinpoint problems within these components, allowing for repairs to be targeted to the specific issue.

Going Beyond Basic Checks: The AI doesn’t just find things; it analyzes them too. It can use LiDAR data (a special type of laser scanning) to examine concrete pillars for cracks and tilts, helping to improve safety assessments.

Managing Vegetation Growth: The system can efficiently identify plants and trees near power lines. It even calculates how tall they are, how close they are to the lines, and the overall area they cover. This information helps pinpoint areas where vegetation could become a hazard and needs to be addressed before it causes problems.

Ensuring Safety Compliance: Based on the voltage of the power lines, the AI can identify areas that require extra safety precautions. This helps ESO comply with safety regulations and keep everyone safe.

References:

1. Ai Power Grid Inspection: Eso Case Study

Industry: Electrical grids

Vendor: EasyFlow Tech

Client: ESO

Keywords: AI-powered quality inspection, AI in quality control, AI-Powered Power Grid Inspection, AI-Driven Inspection Analytics

Previos Article AI Quality Control Ensures Premium Lamella Flooring Quality

Next Article Ensuring Medical Device Safety with AI-Powered Vision